This project was presented for Sounding Rocket part (REXUS).

ARRE System

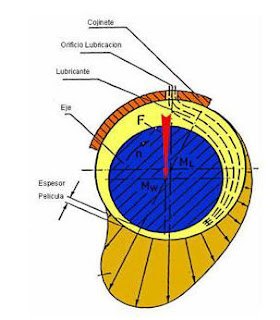

The main purpose of the ARRE will be the study of the re-entry systems based in auto-rotation property. This system is seems the autogiro's system and the re-entry system "Roton". The difference with these programs is the blades’s position, basically by having an offset between the blades and the rotor axis.

This experiment will try to recover a capsule with a payload after being released from REXUS rocket during nose cone ejection.

Low orbit re-entry speed is developed due low mesospheric drag, allowing the experiment reach high free fall speeds before entering the troposphere.

During the mesospheric branch, the rotor blades will fully deploy, having in mind the study of possible drag at these altitudes. While the atmosphere is not dense enough to generate any significant lift, the blades will trying to recover some energy in “windmill” configuration, converting it to the highest possible spin speeds. This speed will tell us how much interaction we obtained during mesospheric flight.

As in stratosphere the density begins to grow, the accumulated spin energy will be used to damp slightly the free fall acceleration. The rotor has variable AoA (angle of attack) mechanism, allowing some actuations. After the “windmill” configuration stage, the blades will track an optimal autorotation profile so maximum energy is recovered and goal descend speed can be archived.

The blade´s airfoil will be optimized through multidisciplinary approach, so extreme performances of whole system could be archived.

Rocket placement

Inside the REXUS rocket, the ARRE experiment will sit inside the nose cone.

This placement is necessary because to the experiment should be released in upper layers of the atmosphere and there is no need in precise apogee positioning, so the experiment can just be thrown off with the nose cone,

Flight Stages

The experiment in the Rocket, the control system will be in stand-by before the launch. The system will be just recording data of the temperature sensors and control heaters.

- At T0 seconds, in the launching moment, the control system initiates the second stage. This stage will record data from the IMU and temperature sensors and control heaters.

- At time T0+60 seconds after launch, on the nosecone ejection, the system will initialize heaters on the electronics and blades angle’s sensors.

- At T0+66 seconds all sensors will be activated in the separation moment.

- At T0+150 seconds in the apogee point, the pyrotechnics will initiate and release the blades.

- After the apogee point the system will be in a controlled falling while the auto rotation system will decrease and control the falling speed. The control system will try to reach the landing point with GPS flight control and IMU stability control.

- Near to the landing point, the ground proximity sensor will activate and initiate rotor engine to provide a softer landing.

In the ESA is typic develop in each mission patch

Our Patch of mission was the famous image that the knight Quijote goes against a windmill.

|